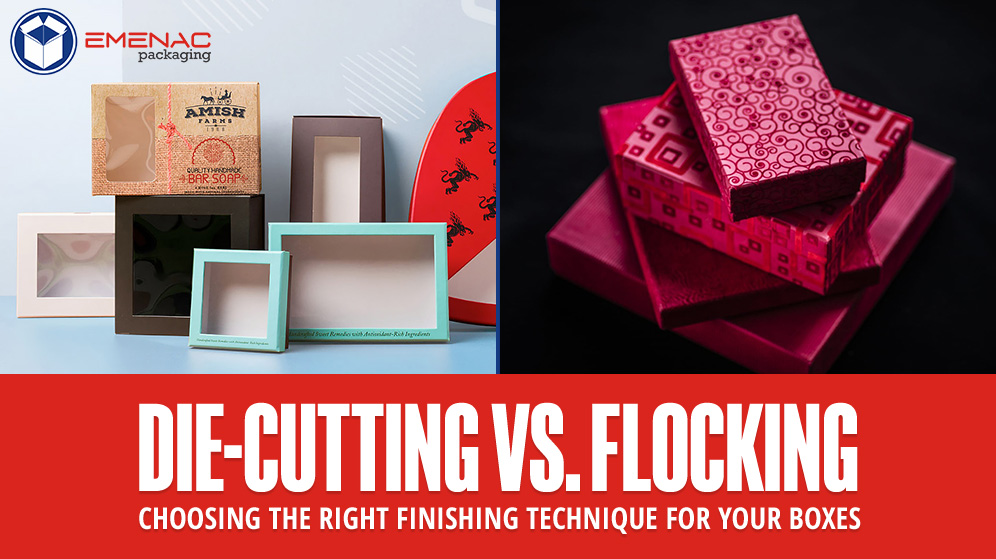

Die-Cutting vs. Flocking: Choosing the Right Finishing Technique for Your Boxes.

When it comes to packaging finishing, there are various finishing techniques to be used to give your packaging a luxurious and appealing touch. Besides other types, die cutting vs flocking is trending nowadays and a lot of people don’t know how a flocking will give their packaging an elegant and branded look. Both of these finishing options come with several benefits and it may be critical for you to choose between both to make its product packaging stand out on the shelves, but there’s no need to worry. In this blog post, we are going to guide you on die-cutting vs flocking and help you choose the right finishing technique for your boxes. Read on!

What is Die-Cutting?

Die cutting is the process of shaping and crafting custom designs from versatile packaging materials. With the latest advancements and technological methods, you can perform the die-cutting process to give your packaging an extravagant look. It all is possible with the help of a die-cutter to create intricate shapes and designs. Die-cutting provides some of the following benefits:

- Customization:

Die-cutting comes with unlimited customization options to choose from and you can easily go for one which you want for your custom boxes. Whether you want a distinctive cutout logo or an unconventional box shape, the die-cutting process enables you to go for the way that helps you make your product packaging stand out.

- Makes your Brand Visible:

By using die-cutting elements in packaging designs, you have the best opportunity to make your brand visible in the competitive marketplace. Using windows or cutouts on custom boxes can give you a competitive advantage over other competitors.

- Enhanced Functionality:

If you want to improve your product packaging functionality, die cut is one of the best options. If you want to make your customer’s unboxing experience memorable and easy, you can add perforated tear strips so they can easily open the box without having any difficulties.

What is Flocking?

In this finishing technique, tiny fibers can be applied to custom-printed boxes. These tiny fibers are made of nylon, polyester, or rayon to the material surface by applying the adhesive. This would give your packaging a luxurious feel as it comes with a soft and velvety texture. It offers some following benefits:

- Provides Versatility:

One of the major advantages of flocking is that it can be easily applied to any type of material from cardboard to paperboard. Whether you want to use it on custom jewelry boxes, perfume boxes, or electronic packaging, it will add a touch of elegance and sophistication.

- Tactile Sensation:

This type of finishing comes with tactile exploration and engages customers to a greater extent. The velvety texture and soft feel create a premium that adds value to your product packaging and attracts customers to a greater extent.

- Visual Impact:

Other than its tactile appeal, flocking can enhance your product packaging’s visual impact. You can make your logos and packaging designs stand out by using this kind of rich texture. By doing so, you can increase your brand sales and capture customer’s attention.

Which One Technique is Best?

When deciding between both of these finishing options, you should consider some of the following factors:

- Brand Image:

First, you need to consider which type of image you want to portray for your brand. If you want to go for a modern and sleek aesthetic, you should go for die cutting but on the other hand, if you want to give your product packaging a luxurious and sophisticated touch, consider going for flocking.

- Type of Product:

Next, you need to think about your product’s nature and packaging requirements for different products. If you are a cosmetic or food business owner and want to go for appealing and luxurious finishing, die-cutting would be one of the best options. On the other hand, if you want to evoke luxury, you can go for flocking as it’s an ideal option for the packaging of luxury items.

- Budget:

Consider your budget in which you have to finalize how much you want to spend. If you want to go for die-cut intricate designs, you have to pay higher costs as compared to the flocking. On the other hand, you don’t have to pay more for flocking finishing.

- Customer Preferences:

Lastly, you have to consider your target audience preferences. Conduct thorough and complete research and find out what best suits your customer’s needs or what type of packaging finishing they want from your brand. By doing so, you have an idea of which finishing technique works best by considering the customer’s needs.

Final Words!

Die cutting and flocking provide you with several distinct advantages in making your product packaging stand out. By understanding the advantages and considerations, you have an idea of which one works best, and it will help you make an informed decision about going for the right finishing technique. Whether you go for the die-cutting option or you want to apply flocking finishing on custom-printed boxes, both of these can give your packaging an extravagant look while leaving a lasting impression on customers.